Smart material

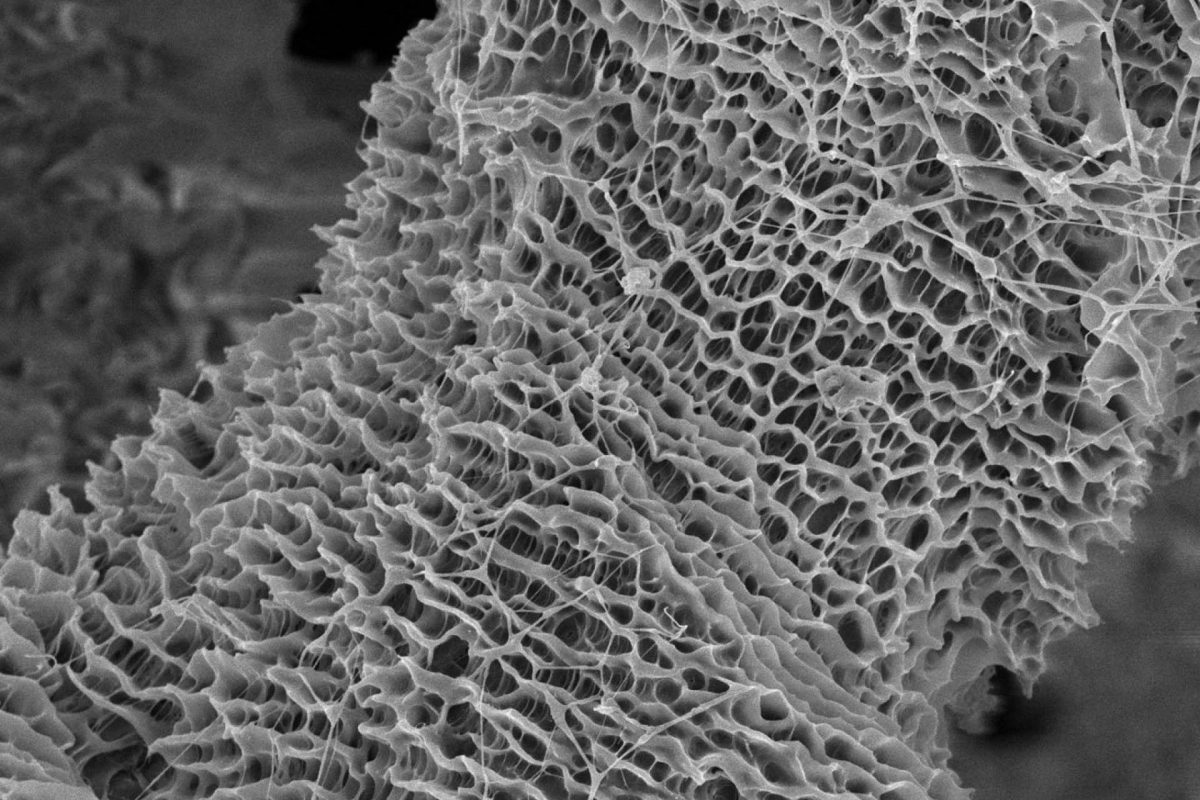

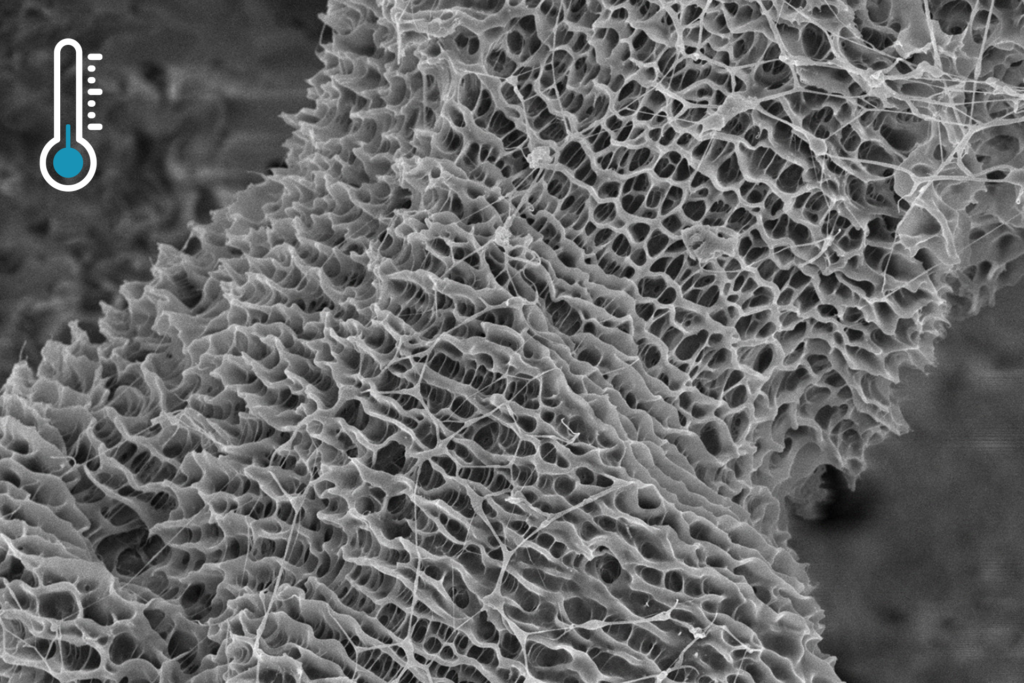

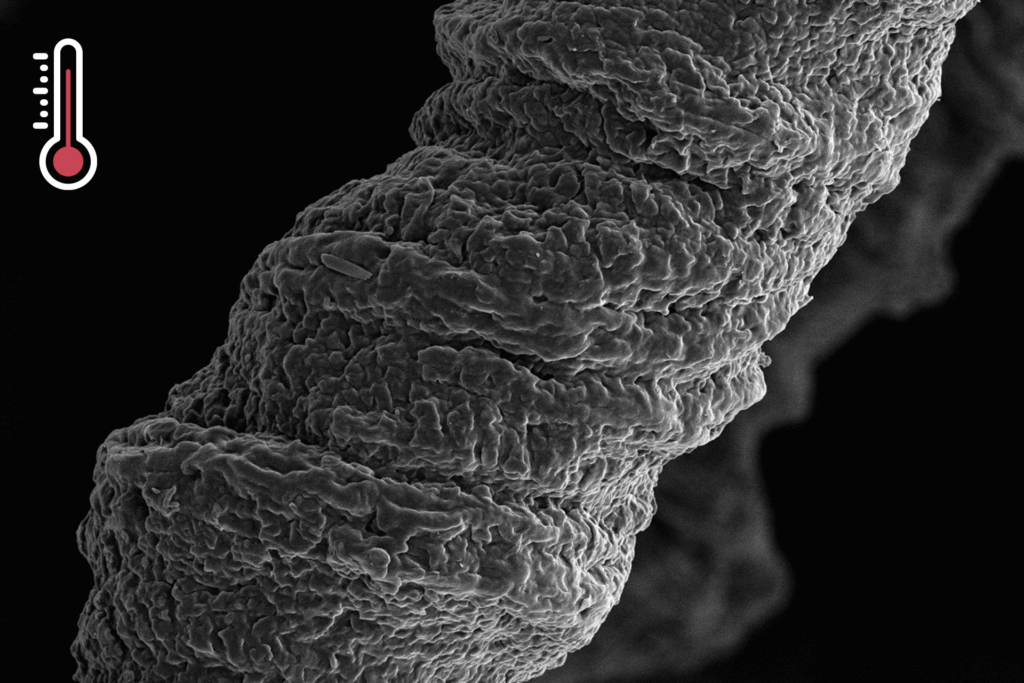

Looking at how nature works in dry coastal areas, researchers at Eindhoven University of Technology developed a temperature-sensitive smart textile. At night, when temperatures are low, the material is super-hydrophilic. This means the material attracts water and absorbs water from the air. The fibres swell up 4 times their size. During the day, when temperatures rise, the material turns super-hydrophobic. This means the material repels the water. The fibres contract and squeeze-out the water like a sponge. Hence our name.

Preliminary research at the university shows that the material is able to absorb and release water over 3 times its own weight each cycle. This way, the material absorbs water from the air every night and releases it during the day. The material is expected to work in dry coastal areas with humidity levels over 70% at night and sunshine during the day.

This way, water can be produced autonomously using the natural temperature cycles of day and night. Completely off-grid and without the addition of energy.

See this video of how the material works under the microscope.

The potential applications are massive: irrigating crops, regenerating desert lands and producing drinking water. But also dehumidifying closed systems, like greenhouses. Based on initial traction, because we can apply the material ‘as-is’ and because we believe our material should be used to benefit our planet, Sponsh first focus is on reforestation.

Note that we are in the development phase. However promising the material may appear in the lab, in the end it comes down to how well the material performs in real life. We are therefore currently improving the material, scaling it up, testing it in real life conditions and adjusting it.